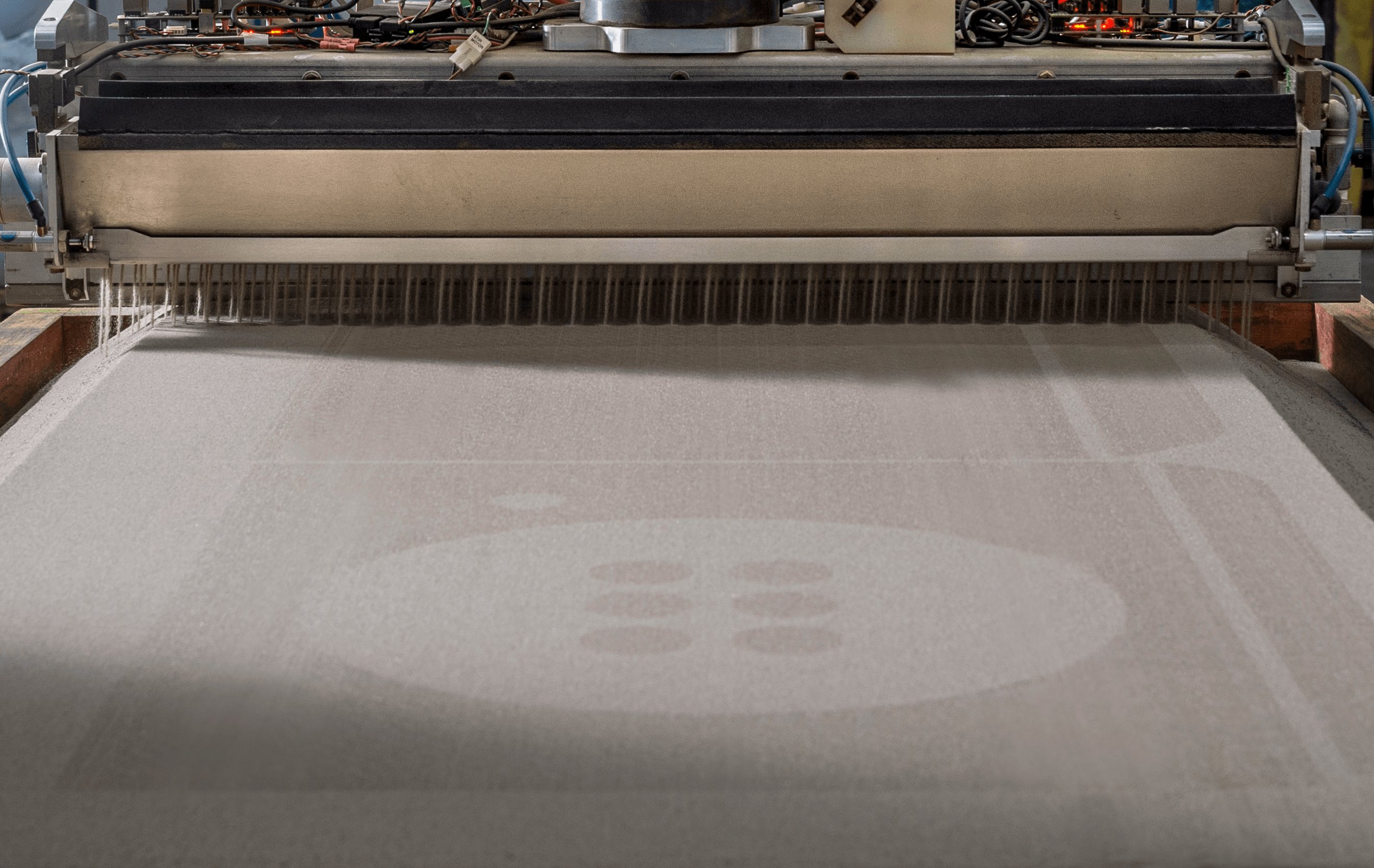

At Ashland Foundry & Machine Works we supply complex, highly engineered castings for a variety of industries and applications. We offer a comprehensive range of services to handle jobs from the concept stage all the way through to finished casting. At our foundry, the sand casting equipment is automated and state of the art, and technical teams utilize a potent mix of software tools to optimize mold designs and process parameters to achieve the best quality results.

Located in Northeastern Pennsylvania, Ashland Foundry and Machine Works runs a no-bake molding line to produce large, heavy castings with dimensions of up to 8′ long x 8′ wide x 5′ high and weighing as much as 10,000 lbs.

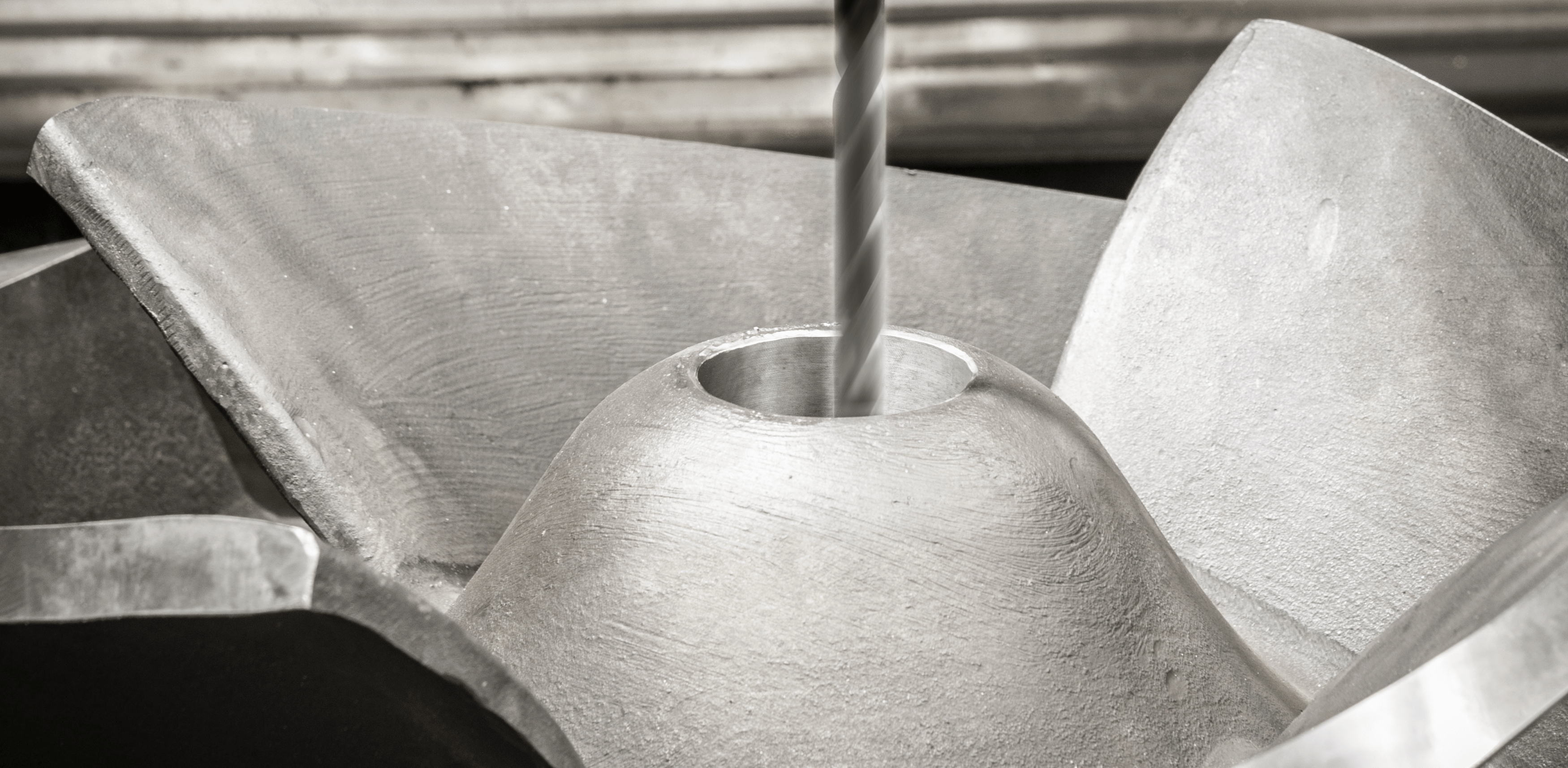

Along with aluminum bronze, stainless steel, carbon steel, and high-performing corrosion, wear, and heat resistant alloys, we process an extensive selection of other ferrous metals. For projects that involve secondary processing, we offer full on-site finish machining, heat treating, welding, and finishing. Our facility also includes a world-class test and inspection department, and we supply quality metrics per customer specifications. We have no minimum order and welcome orders that involve high volumes.

Experienced across a broad spectrum of industries, we furnish alloy castings, stainless steel castings, aluminum bronze castings, and more with complex design criteria.

You might say that Ashland Foundry and Machine Works is a:

- Heat Resistant Stainless Foundry

- Inconel Foundry

- Stainless Steel Foundry

- East Coast Foundry

- Precision Machine Shop

Working in concert to fulfill your needs for cast duplex stainless steel, Inconel, various stainless steel grades , machined castings ready for your assembly line.

Contact us directly to learn more about our ISO 9001 certified casting services.